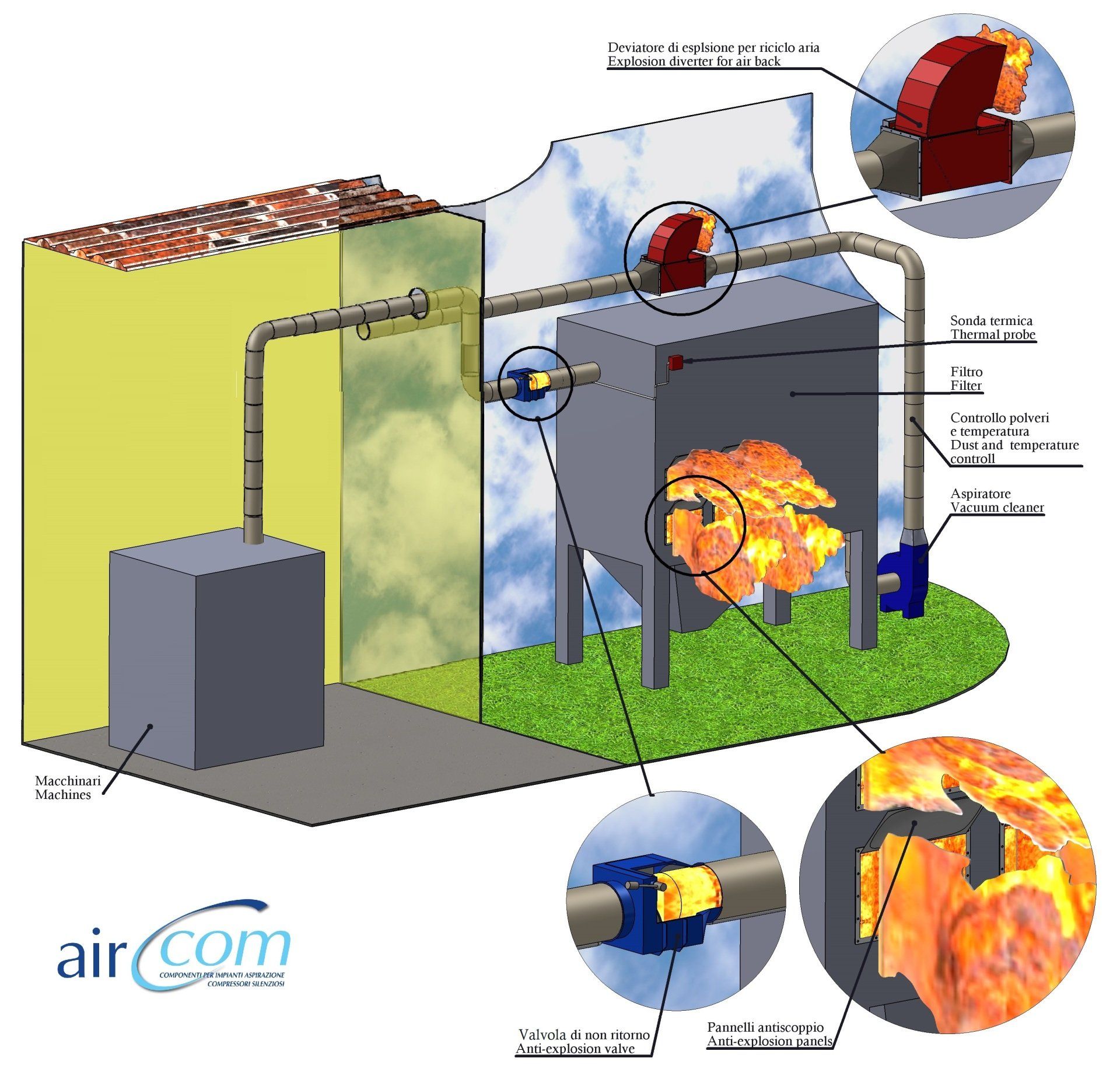

The workplace is a place where the most serious accidents can occur, some of which can even result in the death of people and the destruction of equipment and buildings. Industrial extraction systems always contain a container where waste material from processing is deposited. A fire can develop within the container, which could be a filter or silo, leading to an increase in internal pressure, resulting in an explosion. As you can imagine, the explosion causes the deflagration and total destruction of the container, but also damages everything in its vicinity, both people and property, with the risk of even fatal injuries. This is the main reason why container explosion protection is necessary. These protections save on the cost of the container in the event of an explosion and eliminate the risk of damage around the filter/silo. HOW TO PROTECT THE FILTER OR SILOS FROM AN EXPLOSION: Explosion vent panels are the main elements required for explosion protection. These are elements that rupture at a certain pressure (which must be lower than the pressure supported by the filter or silo), allowing the burst pressure to escape. To ensure safe operation, they must undergo certification tests that comply with European EN standards. All explosion-proof panels produced by Aircom comply with these standards.

Aircom Fairs and Events

Aircom specializes in the production of industrial vacuum cleaner accessories in Nervesa della Battaglia. Always committed to innovation and customer satisfaction, it participates in various trade shows and events every year.

HOW AND WHY TO PROTECT YOUR FILTER OR SILOS FROM AN EXPLOSION

PRESSURIZATION CENTRAL FOR FIRE-FIGHTING AND FIRE-EXTINGUISHING SYSTEM

SOLUTIONS FOR PLANT OPTIMIZATION

PROTECT YOUR SYSTEM:

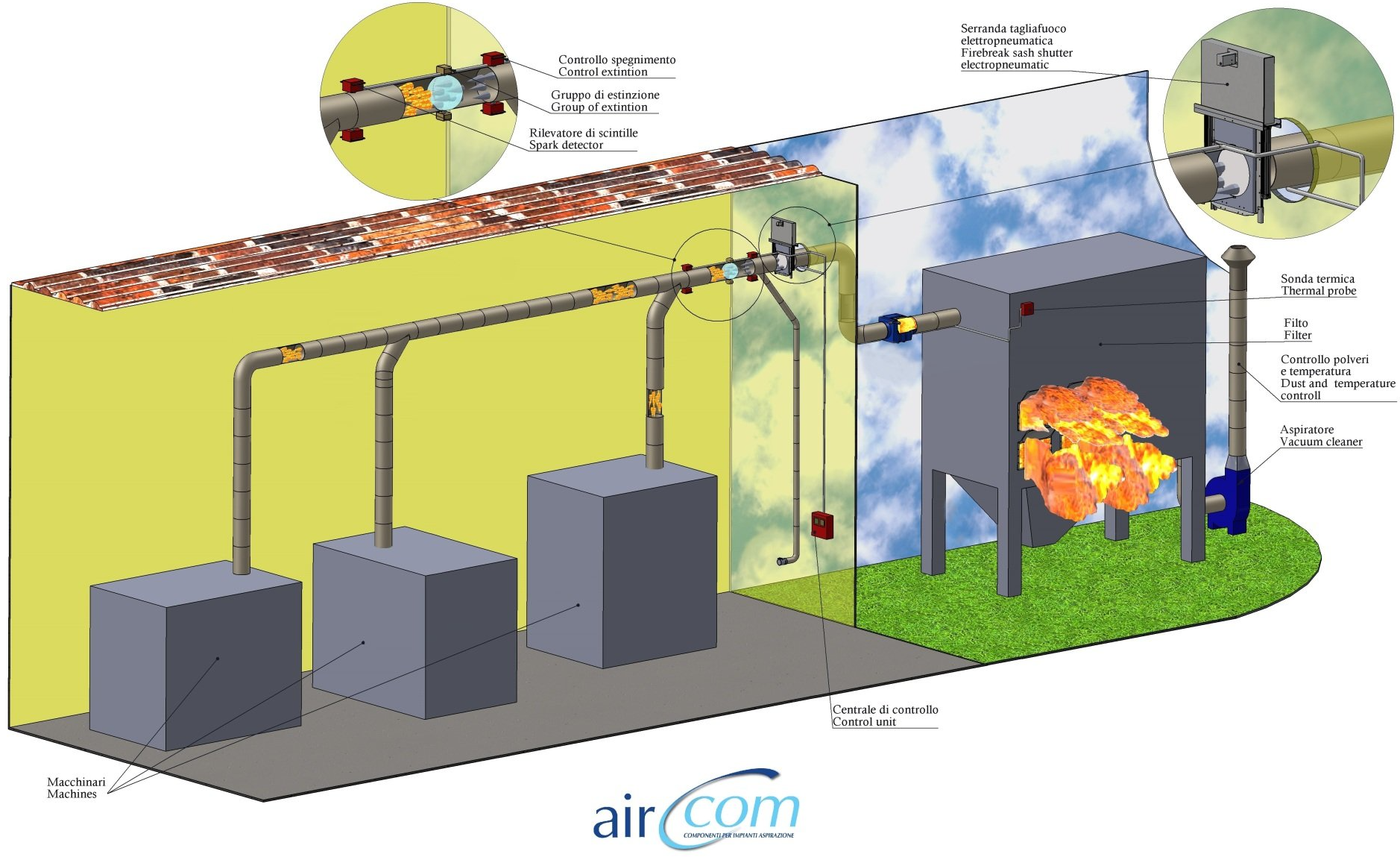

SAFE AND EFFICIENT FIRE EXTINGUISHING SYSTEMS

Extinguishing a fire or sparks in the suction pipe, which have been ignited by the processing of materials, requires great care to ensure effective extinguishing and avoid damage to the production system.

This system presents several problems and thanks to our experience in producing certified fire systems in extraction systems, we have highlighted some precautions that should not be overlooked:

- The type of extinguishing material to be used in the materials being processed

- The extinguishing liquid delivery system

- The system for controlling the presence of flame or spark in the pipe

Type of extinguishing material

The extinguishing material must be related to the type of material being processed, the waste of which is aspirated during processing and passes through the pipeline.

Water is used for most materials, but for some it is appropriate to use other types of liquids or gases; in both cases, a dispensing system appropriate for the material being used is required, in compliance with current regulations.

Delivery system using water as an extinguishing agent

The reference standard requires a nozzle pressure of 4 bar, which is normally not available in the civil water supply line, therefore it is necessary to equip the extinguishing system with a pressurization plant that ensures a constant pressure of 4 bar for the cycle of interventions that each company plans.

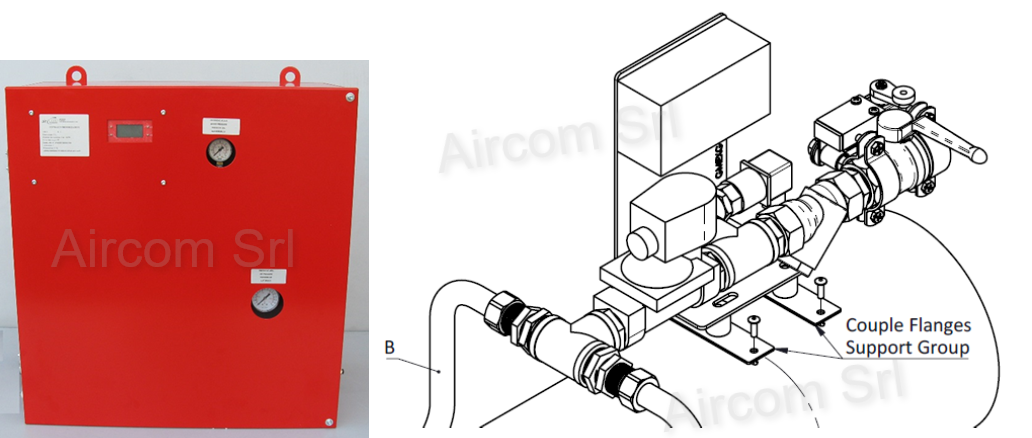

Pressurization plant

It is important to choose the control panel that best meets your needs, with the least maintenance and surveillance issues, avoiding unnecessary costs and further problems.

The main models on the market are of 2 types:

1- Using a Electric PumpThis activates when an alarm signal is received and pressurizes the water in the nozzles. This model requires frequent functionality checks, and if installed in an ATEX zone, the problems would become more complex.

2- Use of the

air and water pressure: this model is part of the company's industrial line and does not require any maintenance, has no motors and does not present any problems if installed in an Atex area.

This CPR model designed by Aircom guarantees 4 bar output pressure for 2 or 3 shut-off cycles and resets automatically.

Flame or spark control system

Before the extinguishing system, it is important to install flame or spark detectors at an adequate distance. This is calculated based on the air speed in the system and the reaction time (sending the signal from the detector to the control unit and then to the solenoid valve that opens the water towards the nozzles; in total, it is approximately 150 ms + 10-20% safety margin to be verified with the manufacturer) of the entire system.

Careful installation of the Flame or Spark Control and Extinguishing System prevents significant damage to the Filter, the company structure and to people in particular.

ANTI-EXPLOSION PANELS

Explosion protection: the importance of explosion-proof panels

In the workplace, it's crucial that safety comes first. Indeed, for those who work, it's crucial to work in appropriate conditions, as danger always lurks.

Why install explosion-proof panels?

As regards extraction systems, one of the main sources of danger is an explosion that can occur in the FILTER or SILOS, which is connected to the extraction system inside the workplace.

The damage that an explosion can cause is always considerable, which is why it is necessary to install devices in your system that reduce its effect and damage.

Filters or silos, in which the contained material could act as a trigger, must be equipped with EXPLOSION-PROOF PANELS at breakage with predetermined pressure.

The Panels have a flange for fixing to the wall of the Filter or Silo and when a pressure higher than the pre-set sealing pressure arrives they open, generally at a pressure of approximately 0.1 bar.

Installation: Safety and Compliance

In the event of an explosion, the pressure inside the container (Filter or Silo) increases exorbitantly, this phenomenon causes the Explosion-Proof Panels to open and allow the pressure to disperse into the atmosphere, safeguarding the container and everything around it, including people.

When installing the panels, it is of fundamental importance to always take into account the installation position, in relation to the floor and/or the passage of people.

This type of device must always be installed at a height higher than 5-6 meters from the ground or from the presence of people. If this basic rule cannot be respected, the explosion vent must be channeled upward.

When is the filter inside the work environment?

When the filter is located inside the work environment, another possible option to consider for protection against the effects of an explosion is: this situation can be resolved by installing a FLAME BREAKER close to the panel: this is a protective element, designed with a special structure, which must always be certified according to current regulations, and which completely blocks the flame, considerably reducing the air pressure of the explosion, allowing for safe transit at a distance of less than 5-6 meters.

FIRE SHUTTERS

In all sectors there is a continuous development of manufacturing processes, which is linked to the obtaining and demand for products of ever higher quality.

This increase, however, requires more functional extraction systems to keep the production machines free of material residues, thus achieving a higher quality product.

More work, more efficiency and more protection, three things directly linked to improving production.

Protecting the workplace and people is one of the most important considerations when determining which devices are best for installation, as it is often overlooked and becomes a major cause of damage and explosions.

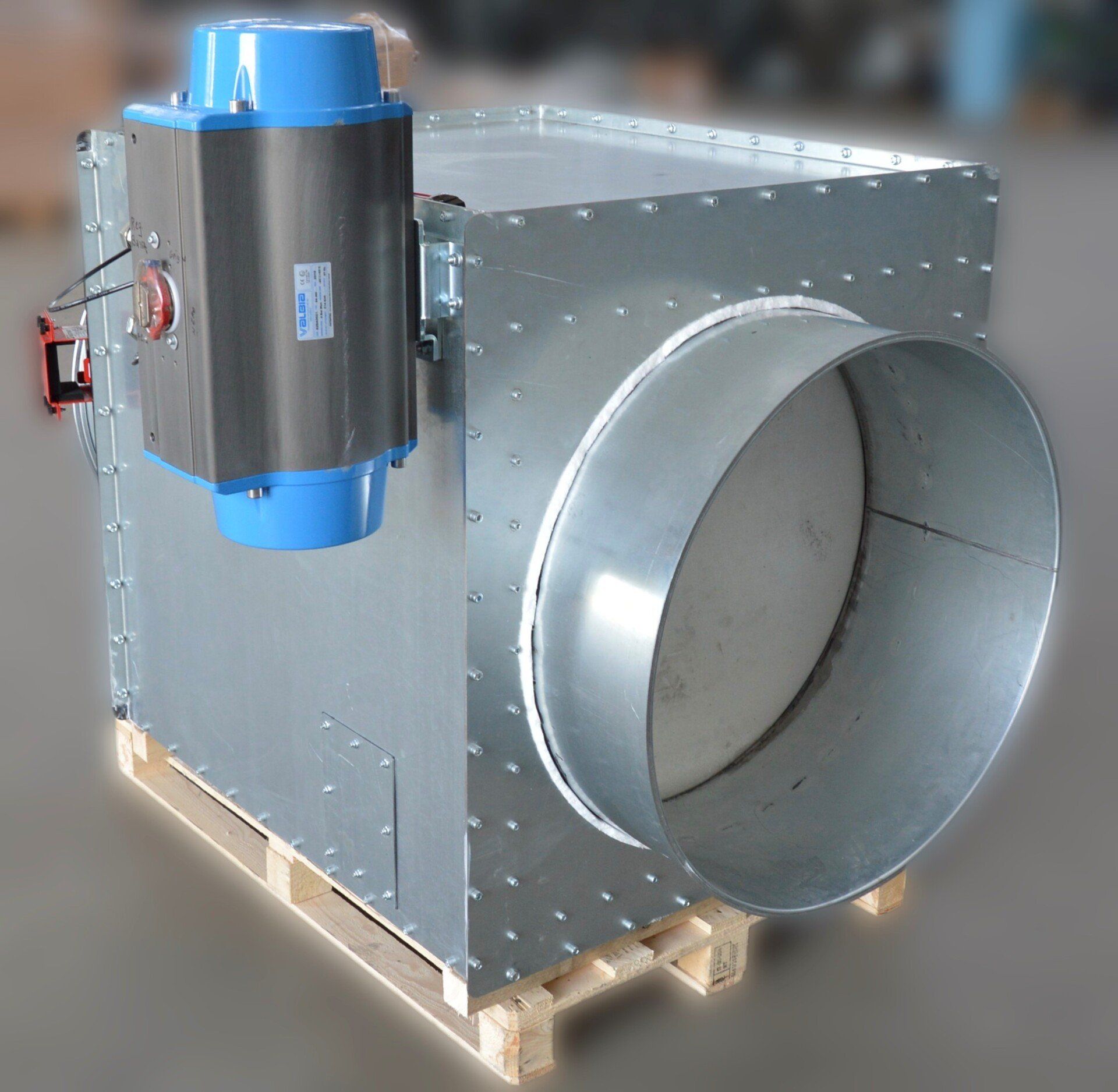

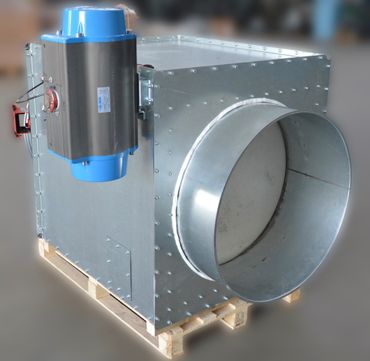

In the event of a fire, a more serious threat to the safety of people and machinery within the workplace is the spread of fire through pipes. This risk can be significantly reduced by installing fire dampers, also in combination with fire detection systems.

Fire dampers represent an insurmountable barrier to the spread of fire, the transmission of heat, and the spread of smoke and flames generated in silos or filters.

There are various types of on the market Fire shutters but to avoid a non-functional shutter during installation, it is necessary to carefully evaluate the most suitable type for your system.

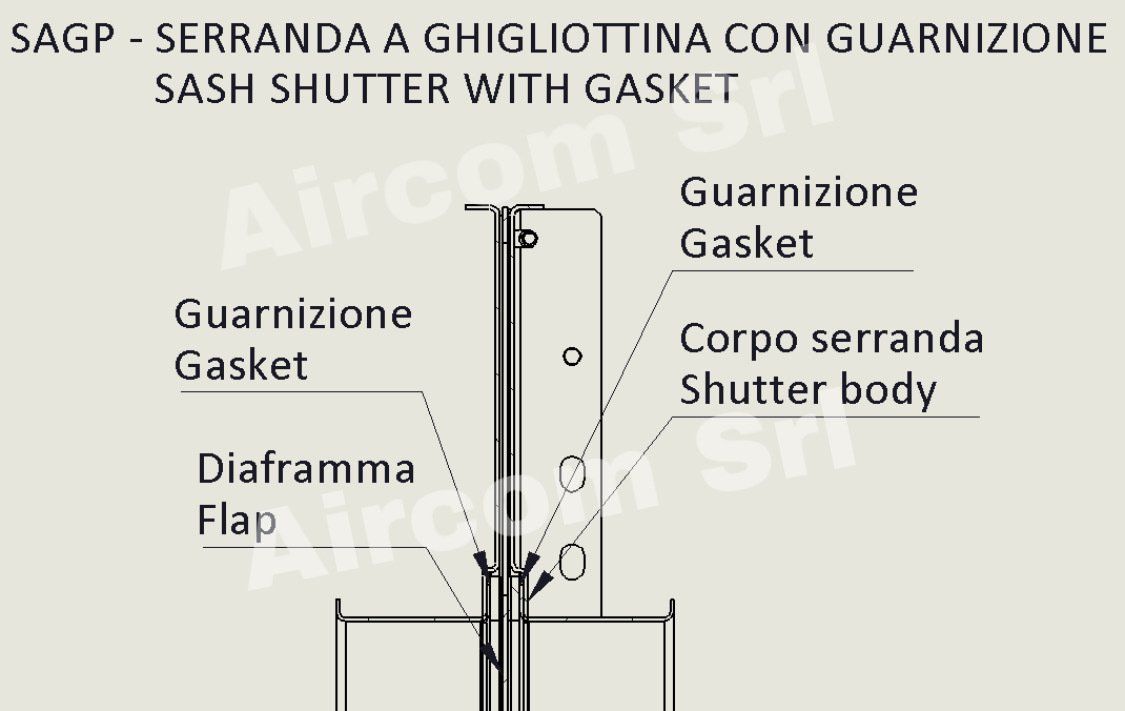

Therefore, if there is passage of material in the pipe, a closure should be preferred which requires the diaphragm to be entirely outside the section of the duct: the models to be evaluated are guillotine or retractable, certified according to the

European Standards EN, like those designed by Aircom thanks to its long technical experience.

We produce a range of fire shutter models that offer you different options, and each model is certified according to European standards, which guarantee fire resistance for 120 minutes.

We offer gravity-operated models: with a 72° (or 108°) fuse, electromagnetic release, and pneumatic reset; electropneumatic with automatic reset for horizontal and vertical piping; and finally, a model with an electropneumatic folding/retractable lock.

The latter could be the most suitable choice especially in cases where the duct is close to the ceiling.

THE FLAME BREAKER

BUT WHAT IS IT?

The Flame arrester It is a device that covers the explosion-proof panel, which is usually installed in the filters or silos of extraction systems.

The special coating of the panel is designed as a structure that stops the flame generated by an explosion in the filter, allowing people or things present in the vicinity of the filter not to be damaged/injured by the flame effect.

WHY SHOULD I INSTALL IT?

More and more often, the spaces available in a company for the installation of the filter/silo of the extraction system are very limited or not available outside the work environment, for this reason they are positioned inside the work environment.

This condition is very dangerous for people and things operating nearby and it is necessary to reduce the effect of the explosion as much as possible as regulated by the EN 16009 standard.

HOW DOES IT WORK?

The Flame Arrester is installed inside the Fire Extinguisher, which breaks when an explosion occurs. The pressure and flame from the explosion pass through its special structure, which cools and extinguishes the flame, thus reducing the pressure of the explosion and allowing transit at distances of up to 5 meters.

Please note that this would be impossible without this particular structure.

The significant difference and effect of the explosion is clearly visible in the photo above: in the free panels, the flame is clearly visible, while in the panels with flame arresters, it is not present. Its use is highly recommended and mandatory in situations where the filter or silo may be approached by people during the company's normal work processes. IT'S SAFETY IN THE JOB PLACE.

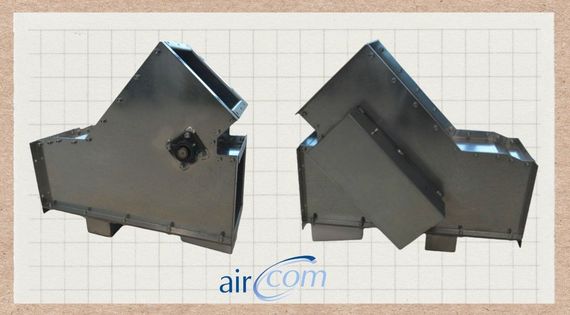

HOW AND WHICH SAFETY DIVERTER TO CHOOSE

There are many types of diverters on the vacuum market, but not many of them protect against damage caused by an explosion.

To reduce the effects of an explosion or prevent it from starting, Aircom has developed 2 important models of diverters:

- DRS or rapid spark diverter

- DEVEX or explosion diverter

The DRS “Dquick spark arrestor” has the function of diverting the spark that can be created during the work process considering that if it were to reach the filter or the silo there would be the possibility of an explosion occurring.

The first technical feature, very important, is the

SPEED OF CLOSING, and secondly, but less fundamental, is to avoid that there is a

PRESSURE LOSS during processing.

In order to function, the diverter must be connected to a spark detector and in a short time (about 100-130ms) the diverter closes the air line to the filter and diverts the spark into the atmosphere.

The model DEVEX “explosion diverter” was developed to divert the effects of an explosion in the filter which, through the pipe, could return inside the building (workplace).

This configuration is used for energy saving reasons, particularly for heating the workplace in the winter. Another important aspect is that it prevents the explosion from reaching the workplace.

This device

DOES NOT BLOCK the explosion but the

DEVIA; this is a very important aspect to remember and pay close attention to in order not to use it incorrectly.

When choosing an explosion diverter it is necessary to take these important technical features into consideration; the DEVEX Aircom are equipped with a triple closing actuation system:

1. Activation of closure in case of blackout;

2. Closing activation via signal from a flame detector, spark or other sensor;

3. Activation of closure with overpressure generated by an explosion only on request (moving band)

AIRCOM projects prioritize workplace safety, but also offer a way to save energy in the company's production process.

QUICK SPARK SWITCH - DRS

The quick spark diverter It's a fundamental device in industrial vacuum systems. It's designed to quickly and precisely divert sparks generated during certain processes on your products and sucked up by your vacuum system, preventing them from ending up inside your filter and potentially causing fires or explosions.

The rapid spark diverter must be managed by a control unit with a spark detection system. When the detector detects one or more sparks, it triggers the rapid spark diverter, thus diverting the hazard into another pipe. This process occurs very quickly, allowing for the management of high-frequency events.

Where can the quick spark diverter be installed?

- Push suction systems

- Pull extraction systems

What are the advantages of installing a spark diverter?

- High response speed: allows you to quickly divert sparks;

- Versatility: usable in push and pull.

In conclusion, we can define the rapid spark diverter as a simple but effective technology in protect your system from possible sparks that can end up inside your filter.

Its ability to deflect sparks precisely and quickly is a

safety for your extraction system.

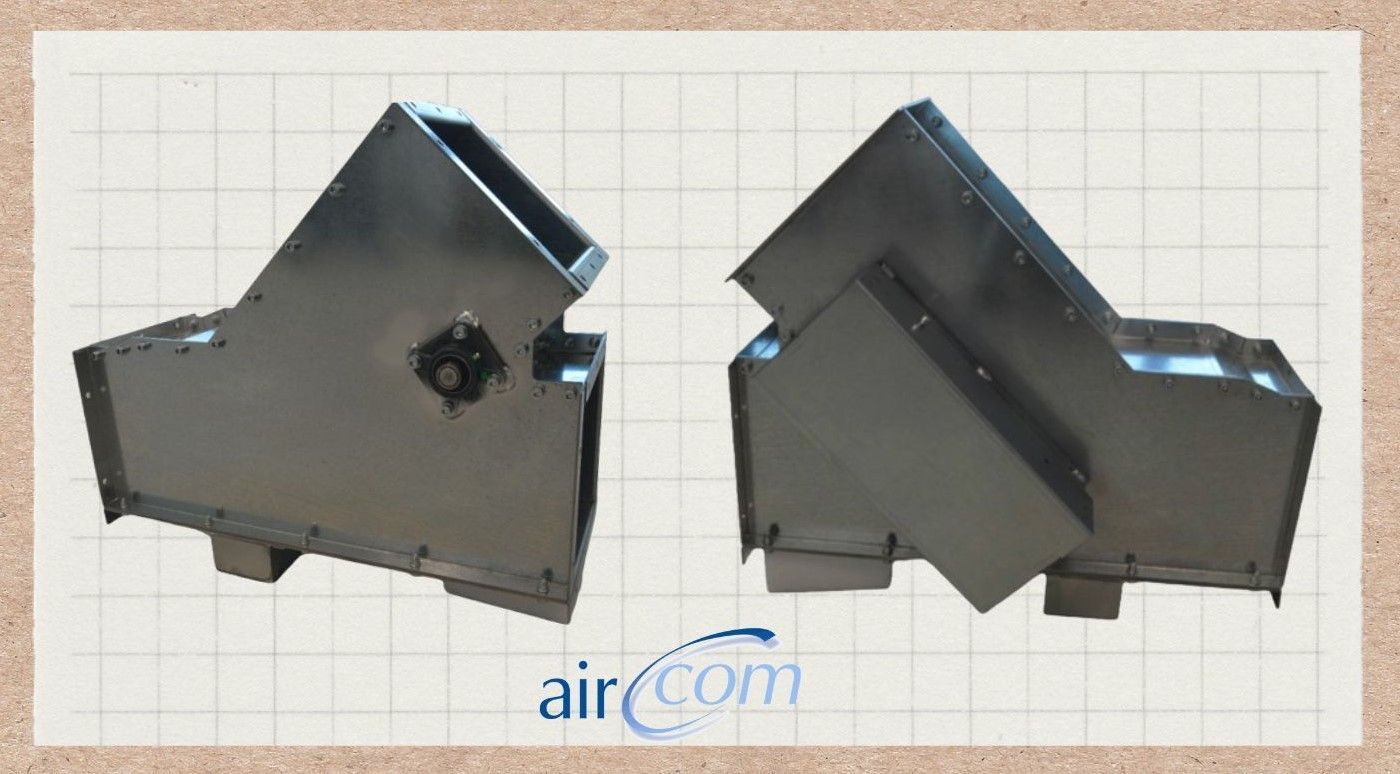

RETRACTABLE SHUTTERS

To provide the installer with a valve with greater safety and functionality but which does not take up too much space when open, Aircom has created retractable dampers.

The advantage of these valves is that they leave the waste material passage section completely free; the installation of this type of valve means that there is no significant pressure loss.

Aircom concealed or drawer shutters can be of different types:

- Manual

- Balance

- Sealed pneumatics

The choice of drive must be evaluated to achieve the desired objective in the suction system

All models can be supplied Standard or with ATEX II 2GDT6/T85°C certification.

In the latter case, all sources of possible sparks are eliminated with suitable material (where necessary) and in the case of pneumatic shutters, certified products are used.

ATEX.

TRAINING AT YOUR FINGERTIPS

Knowing how products work is not always enough to ensure correct installation.

For this reason, AIRCOM has decided to hold training courses without you leaving your workstation!

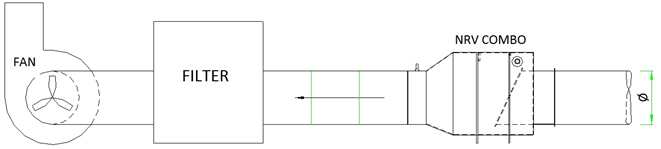

The need arose during the lockdown period, when we were often asked to work on existing installations due to system modifications. To ensure an after-sales service that supported both the customer and the installer, we decided to hold training courses primarily on: Non-return valves (NRV COMBO and METAL Series) and on Fire Shutters directly online with the aim of training operators on their correct operation, installation and maintenance.

Given the ever-increasing demand, we have expanded the range of products to include in the training of our staff and, based on your needs, it is possible to create a customized program based on the products of greatest interest.

You can contact us at aircomtv@aircomsrl.it to schedule the dates, times, and topics of the training course. Upon completion, you will be issued a training certificate.

HOW TO ENSURE THE CORRECT OPERATION OF A NON-RETURN VALVE

The cleaning system is one of the Aircom accessories that can be mounted on the Non-Return Valves Aircom.

WHY INSTALL THE SYSTEM?

During normal operation of the extraction system, residues of waste material may deposit on the lower part of the valve. To ensure proper operation of the damper and to further ensure that nothing is affecting its operation, a capacitive sensor can be installed on the bottom of the valve to detect and monitor the presence of deposited material.

WHAT IS THE SYSTEM FOR?

Installing the cleaning system prevents the formation of dust or debris buildup, which could prevent the diaphragm from closing properly.

The sensor, which detects the presence of material, can be integrated with a compressed air blowing system, which moves the pile of deposited material.

The cleaning system can be mounted on non-return dampers from Ø200 to Ø1200

Maintenance for proper operation

Maintenance of NRV check valves is necessary and mandatory, according to the instructions in the manufacturer's manuals, to ensure proper valve operation. Valve maintenance is always divided into two types: ordinary And extraordinary.

Routine checks are carried out at various time intervals depending on the operations to be carried out.

Below are the intervals to be carried out for the various ordinary maintenance operations (naturally these are indicative at the discretion of the manufacturer), but depending on the type of materials treated and the frequency of work, they can be intensified or reduced;

VERY IMPORTANT: this type of evaluation should be considered only after some ordinary maintenance indicated by the manufacturer:

| POS. | OPERATION TO BE PERFORMED | FREQUENCY |

|---|---|---|

| 1 | General visual inspection | 1 month |

| 2 | Check that there are no material deposits on the bottom of the valve. | 3 months |

| 3 | Check the free rotation of the diaphragm pins and the operation of the anti-opening locks | 3 months |

| 4 | Check the condition and tightness of the nuts | 6 months |

| 5 | Check the ground connections of the protection system | 6 months |

As for extraordinary maintenance, this is performed when unforeseen events occur, which have compromised the correct functioning of the valve.

ATEX REGULATIONS: HOW AIRCOM MEETS SAFETY

The ATEX Directive 2014/34/EU, which came into force on April 20, 2016, applies to all products (electrical and mechanical) intended for use in potentially explosive atmospheres. It also defines the characteristics that products installed in potentially explosive atmospheres must meet, and also provides the various procedures required to achieve compliance.

To help installers choose the most suitable product for their specific system, Aircom offers a line of ATEX Group II certified products.

In the directive, products are divided into 2 groups of materials:

- Group I: Products to be used in firedamp-prone mines

- Group II: equipment intended for surface use

The group we are going to analyze are the Group II products; for this equipment there are 3 categories:

- Category 1: systems that guarantee a very high level of protection;

- Category 2: systems that guarantee a high level of protection;

- Category 3: systems that guarantee a normal level of protection;

However, each category is followed by the letter G (Gas) or D (Dust).

All products, in each category, must be accompanied by the EU declaration of conformity and instructions for use.

Among the Aircom products ATEX certified products are available that are suitable for both Gas and Dust;

In detail:

· Explosion-proof panel: Group II GD

· Foldable Panel: Group II D

· Non-return valves NRV COMBO and NVR METAL: Group II D

· Flame arrester: Group II Category 2 D

Each of these items performs a different function within the system, and it is necessary to have a thorough understanding of the waste materials from the processes to evaluate their installation.

ATEX-certified systems in Italy must comply with Directive 99/92/EC. The Directive classifies workplaces into zones where explosive atmospheres may occur and determines the groups and categories of equipment to be used in each zone.

All our business processes adopt a quality management system compliant with EN ISO 9001:2008. This means that each item is annually audited by external auditors appointed by the notified certification body. Maintaining compliance with ISO 9001 allows us to measure and maintain continuous improvement over time in the products we market and the customer support services we offer. This corporate commitment is maintained to ensure continuity in our corporate strategy, which has always been attentive to the needs and constant satisfaction of our customers.

SHUTTERS WITH GRAVITY CLOSING

The Aircom guillotine fire dampers have the advantage of leaving the pipe completely free and closing almost instantly when needed.

The types of shutters we offer are 4:

1- STFRT

2- STFRT-PM

3- STFRT-MA

4- STFRPCMT / -O

Each of these models is ATEX certified and classified EN1366/2/EN1363-1 REI120/RE120.

Furthermore, it is possible to install the microswitch on all models, either now or later.

For all models except STFRT, the installation of a fire detection system is foreseen; if this is not possible for various reasons, it is possible to mount the fuse holder flange (72°C).

WHICH NON-RETURN VALVE IS MOST SUITABLE?

Following the technical analysis of the system, therefore having examined the material and its KST, IF SUITABLE, we can proceed with the installation of the ATEX EN 16447 certified valve which complies with the European Directive in force 2014/34/EU.

HOW TO DECIDE WHAT TO MOUNT:

When installing the shutter, it is important to take the following variables into consideration:

- The valve diameter;

- Check the type of certification: check that the shutter can be mounted in vacuum or pressurized systems;

- There certification class: T1-T2-T3, the higher the certification class, the higher the degree of protection;

- There type of material with which it was tested: metallic (aluminum) or non-metallic.

- There minimum distance installation distance from the filter or silo allowed: the space required is dictated by the valve closing times, the flame propagation speed and the pressure wave; the maximum distance increases the maximum reduced pressure (Pred,max);

- There pressure drop: the pressure drop experienced by the airflow as it passes through the damper, making it a very important factor. Specifically, the patented AIRCOM design utilizes a counterweight in the diaphragm, which almost completely balances the weight, minimizing the pressure drop caused by the installed valve.

- Capacitive Sensor, which AIRCOM valves are already equipped with, is installed at the bottom of the damper. It detects any deposited material and sends an alarm to the control software. Installation is very easy and can even be retrofitted without making any modifications to the valve.

- Position microswitch, indicates the position of the valve and can also be installed retrofitted without any modifications.

- Timed airflow internal cleaning system, its installation is according to your needs.

This element is important, as the metallic processing residue material has a significantly higher explosive coefficient than non-metallic materials.

Once the installation has been chosen and planned, it will be necessary to provide for the structure of the duct between the Filter and the Valve in an appropriate manner as described in the manual.

USEFUL ACCESSORIES FOR OPERATION

Some accessories that could be very helpful:

Properly functioning extraction systems are essential for quality workmanship and the protection and safety of workers. AIRCOM is constantly seeking the best solutions and offers ongoing support and technical training, including online courses, to customers and industry professionals.

NON-RETURN VALVE: YES OR NO?

LET'S FIND OUT TOGETHER!

In industrial extraction systems, where processing residues are present inside the pipes, there is always a container where the waste is deposited. A fire can break out inside this container, increasing the internal pressure and causing an explosion.

WITHOUT SAFETY DEVICES:

The explosion causes a deflagration and destruction of the entire container, causing very serious damage to people and things nearby, sometimes even fatal.

WITH SAFETY DEVICES:

In the event of an explosion, safety devices (such as explosion-proof panels) installed in the filter or silo vent the explosion, preventing the container from being completely destroyed. They also signal the devices on the line how and when to react, thus reducing damage to people and property in the surrounding area.

PROTECTING THE WORKPLACE FROM AN EXPLOSION:

As mentioned above, protection of the working environment from an explosion is achieved on several levels:

1. The first level is the protection of the Filter with the installation of the Explosion-proof panels,

2. The second level is the protection of the working environment which is achieved with NON-RETURN VALVES

Non-return valves, tested in accordance with the current European Directive 2014/34/EU and certified to Atex EN 16447, must be suitable for the type of material being processed and its explosion coefficient (KST). Their installation instantly interrupts the propagation of burst pressure in the pipes to the work environment.

IMPORTANTFor real and safe protection of the system, it is necessary to have technical knowledge of the structure, both of the Filter or Silo, and of the processing material that is sucked up and deposited in the container.

Different types of waste material vary greatly in explosive power, and underestimating their explosive potential could result in less protection than necessary, with consequent disastrous effects.

CONCLUSION:

A vacuum system without safety devices is extremely dangerous and carries the risk of serious, even fatal, accidents. This is the main reason why container explosion protection is necessary: installing these protections also reduces the cost of the container and any damage that might occur in the explosion.

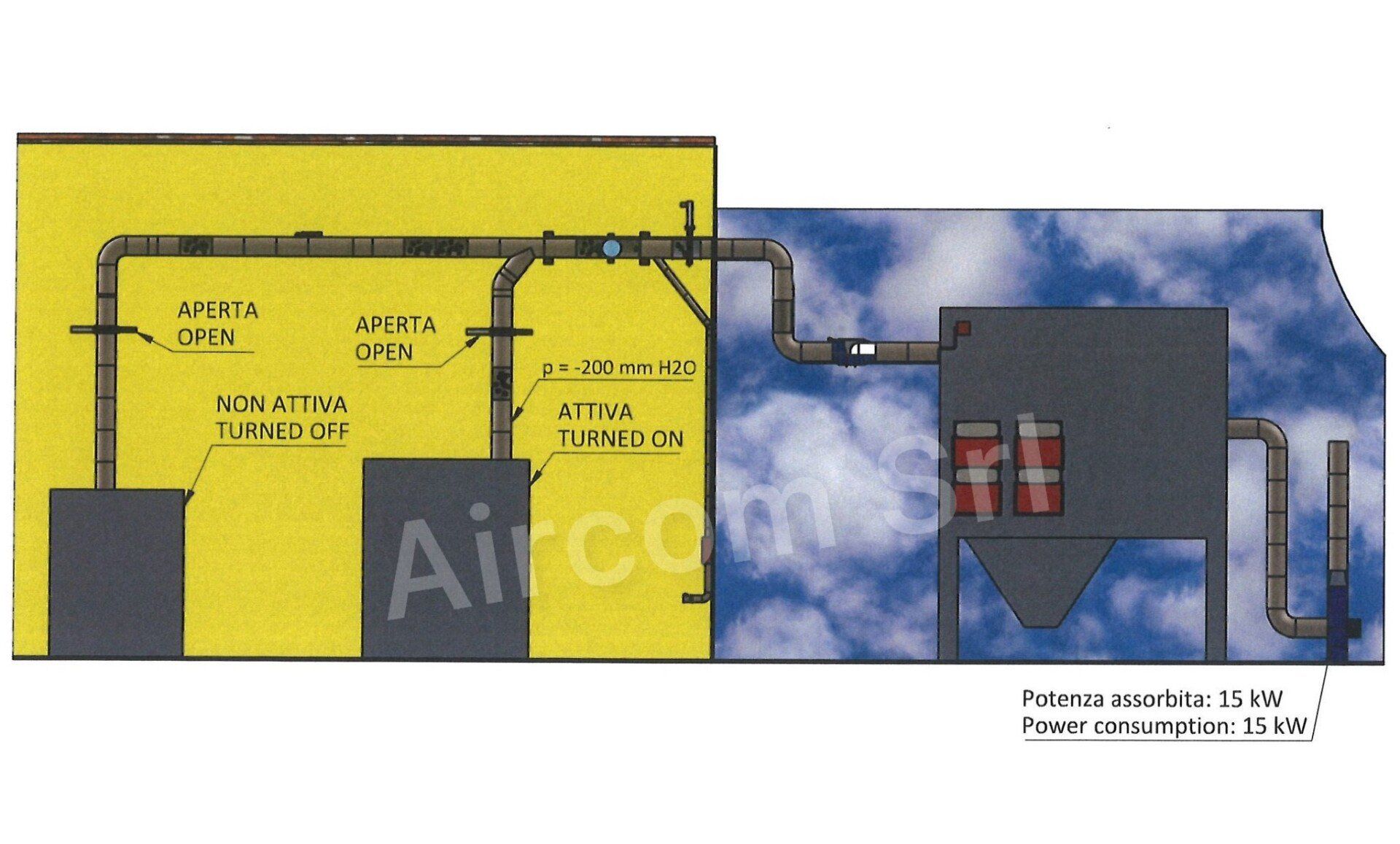

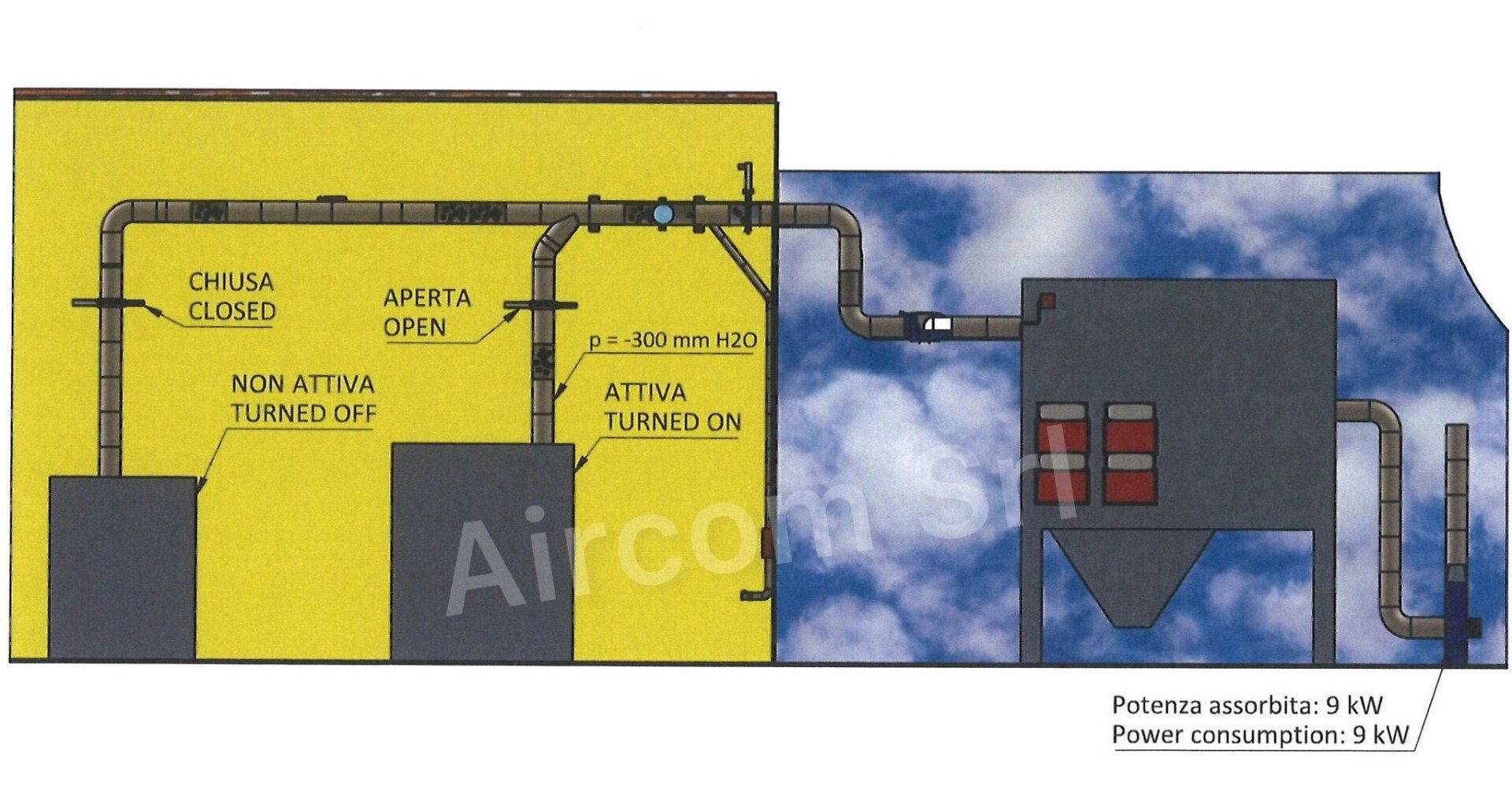

AIR RECYCLING AND PROTECTION IN CASE OF EXPLOSION

The most important thing in a manufacturing environment, where people work to make products, is to try to operate as safely as possible to avoid harm to people in the first place and to equipment and the environment.

The extraction system is an integral part of almost all production processes. The ducts extract the residues of processed materials using an extractor fan and convey the waste into containers. The materials are deposited inside them, and the clean air is released into the open atmosphere or is often reintroduced into the work environment to recover heat and energy, especially during the cold season.

The residues of the material that settle inside the silo can be the cause of an explosion and the bursting of the container.

The filter is protected by installing explosion-proof panels that protect the surroundings of the container. However, if the clean air is reused (returned to the work environment) through a special duct, to protect the work environment it will be necessary to instantly stop the flow of air in the duct towards the production area, so as to keep the explosion outside.

Closing the duct causes the air flow to be diverted into the open atmosphere, and thanks to this change, people and things within the work environment are not damaged.

HOW TO DIVERT THE BLAST

Following market demand, Aircom has designed the DEVEX explosion diverter, a solution to this problem. The diverter is available in various sizes and types, with three diversion safety features:

1- SAFETY WITH MOBILE BAND

2- SAFETY WITH FLAME CONTROL UNIT

3- SAFETY IN CASE OF POWER FAILURE

ANALYZING THE VARIANTS

In the case of the moving band, the air flow is diverted when the explosion flow arrives; with the control unit, however, the air flow is diverted when the flame signal arrives; in the latter case, i.e., the power failure, the flow is diverted when the electrical voltage is lost.

The intervention oftheDEVEXIt involves a diversion of the air flow, eliminating the possibility of the explosion effect reaching the working environment.

It is possible to mount some accessories useful for its operation in the diverter, such as: the sealing gasket in the diaphragm or the diaphragm position sensor.

EUROBOIS 2024

From 06 to 09 February 2024 you can find us in Lyon

AIRCOM awaits you at the Eurobois show from 06/02/24 to 09/02/24 at stand 6 G86!

EUROBOIS is France's leading wood trade fair, bringing together industry professionals for over 30 years. This event will give us the opportunity to meet each other, learn about our products, and learn how they can be applied to your systems.

Come visit us! We're waiting for you!

HOW AND WHY TO PROTECT YOUR FILTER OR SILOS FROM AN EXPLOSION

PRESSURIZATION CENTRAL FOR FIRE-FIGHTING AND FIRE-EXTINGUISHING SYSTEM

SOLUTIONS FOR PLANT OPTIMIZATION

DO YOU WANT TO OPTIMIZE YOUR SYSTEM?

Analyzing production aspects is important for evaluating and designing the extraction system:

-OPTIMIZATION of the plant: the cleaner the machines and production tools are, the higher the quality of the product and the lower the final production cost.

-ELIMINATION OF WASTE: it is important to reduce energy waste, especially when the machinery is turned off.

-ANALYZE THE TYPE OF MATERIAL TO BE WORKED AND THE TYPE OF PROCESSING: these two elements are fundamental to choosing the type of suction and what kind of control to install.

The principle of the suction system is aimed at solving several problems;

Analyzing the situations, Aircom found that the problems could be the following:

1. Remove residual materials in machinery;

2. Cleaning the work environment;

3. Energy savings in both electricity and heating during the winter

TYPES OF VALVES

- VALVE BUTTERFLY

- VALVES WITH GUILLOTINE CLOSURE

- VALVES GUILLOTINE WITH SEAL

- VALVES DISAPPEARING OA DRAWER

HOW TO PROTECT YOURSELF FROM AN EXPLOSION

WHY AND HOW TO PROTECT YOUR COMPANY FROM EXPLOSION DAMAGE

It's a very important question that company managers increasingly ask themselves and ask us.

The first consideration is to avoid harm to people in or near the work environment, and then to avoid damage to the company's facilities and equipment.

How to protect the workplace from potential explosions must be planned when designing a new production line or assessed by considering a company's existing manufacturing activities, taking into account the types of materials involved in the production cycle.

Generally, the explosion occurs in closed rooms where materials derived from processing are stored in the production system, which may be silos, filters or other.

EUROBOIS 2022

ANTI-DEPRESSION ROCKER VALVES AND PNEUMATIC DISAPPEARING VALVES

AIRCOM PARTICIPATED IN EUROBOIS 2020

Eurobois 2020, the woodworking technology trade show, took place from February 4 to 7, 2020, at Eurexpo in Lyon. Over 200 companies registered, over 15 percent of which were new exhibitors, representing all sectors of the woodworking industry, including ourselves.

The four-day edition of the show offered industry professionals a venue for business meetings, networking, and to showcase their innovations. Industry 4.0 and the transformation of the various professions in the supply chain were among the key themes of this edition, both at the stands and during the events and conferences.

The new feature of the 2020 edition was represented by the components and the first transformation sector, which were particularly highlighted.

At the fair, Aircom brought all its know-how, the result of 50 years of experience.